![Small Single Shaft Magnetic Particle Clutches 2]()

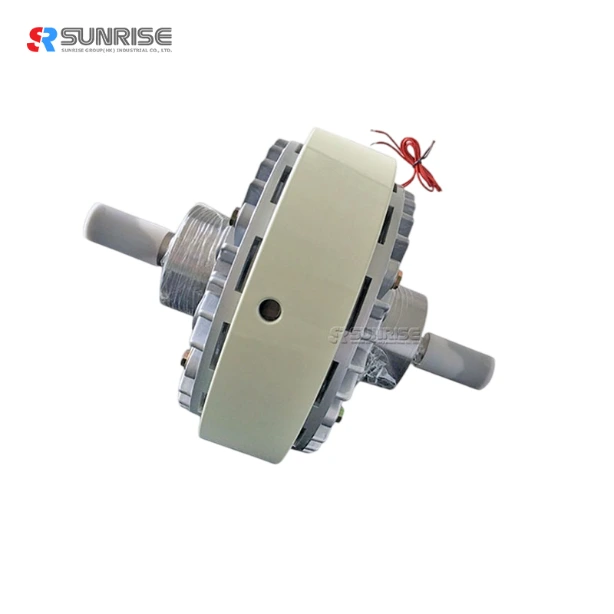

PC Magnetic powder clutch

PC magnetic particle clutch work principle:

Magnetic particle clutch | brake is a type of auto-control component with high-performance which uses driving and driven units as main body, powder (magnetic powder) with high magnetic conductivity as working medium and exciting current as control means so as to achieve control transfer/braking torque and to keep the linear relationship between input current and output torque. With the development of the modern industry, it plays an increasingly important role in all industrial fields and demonstrates great advantages over other components.

CE qualified magnetic powder clutch data:

![Small Single Shaft Magnetic Particle Clutches 3]()

|

| Model | PC-003 | PC-006 | PC-015 | PC-025 | PC-050 | PC-100 | PC-200 | PC-400 |

| Rated torque[kgf-m] (N-m) | 0.3(30 | 0.6(6) | 1.2(12) | 2.5(25) | 5(50) | 10(100) | 20(200) | 40(400) |

Capacity DC24V 75¡ãC | Current(A) | 0.53 | 0.81 | 0.94 | 1.24 | 2.15 | 2.4 | 2.7 | 3.5 |

| Power(W) | 12.7 | 19.4 | 22.5 | 30 | 51.5 | 57.6 | 64.8 | 84 |

| No. of hours set (S) | 0.08 | 0.08 | 0.1 | 0.12 | 0.13 | 0.25 | 0.37 | 0.4 |

| Weight(kg) | 2.5 | 2.7 | 5.2 | 9 | 14.5 | 37 | 53 | 100 |

| Maximum speed (r/min) | 1800 |

| Weight of powder (g) | 7.5 | 10 | 20 | 33 | 60 | 140 | 225 | 370 |

|

Exterior Dimension | D1 | 120 | 134 | 152 | 182 | 225 | 290 | 327 | 395 |

| D2 | 75 | 116 | 126 | 160 | 198 | 256 | 295 | 365 |

| D3(g7) | 42 | 42 | 42 | 55 | 74 | 100 | 110 | 130 |

| D4 | 64 | 64 | 64 | 78 | 100 | 140 | 150 | 200 |

| L | 154 | 164 | 192 | 232 | 294 | 360 | 408 | 500 |

| L1 | 22 | 26 | 29 | 43 | 55 | 65 | 69 | 92 |

| L2 | 98 | 100 | 124 | 136 | 172 | 216 | 250 | 291 |

| L3 | 11 | 14 | 15 | 17 | 30 | 28 | 30 | 35 |

| L4 | 13.5 | 18 | 25.5 | 26 | 28 | 45.5 | 55 | 66.5 |

| d(h7) | 10 | 12 | 15 | 20 | 25 | 30 | 35 | 45 |

| T | 11.5 | 13.5 | 17 | 22 | 28 | 33 | 38.5 | 48.5 |

| W(p7) | 4 | 4 | 5 | 5 | 7 | 7 | 10 | 12 |

| V | M3*0.6P*6L | M4*0.7P*8L | M5*0.8P*10L | M6*1P*12L | M10*1.5P*20L |

| R | 6-M5*0.8P*10L | 6-M6*1P*10L | 6-M10*1.5P*20L | 8-M10*1.5P*15L |

| S | -- | 1/8 | 1/4 | 3/8 |

![Small Single Shaft Magnetic Particle Clutches 4]() |

![Small Single Shaft Magnetic Particle Clutches 5]()

![Small Single Shaft Magnetic Particle Clutches 6]()

* Printing systems: conveyors and in-feeders

*Wood-working systems: saws, wood-working machine, laminators

* Office equipment: electronic copy machines, calculators, fax machines, coin counters, printers

* Testing systems: lab machines, durability testers, measuring systems

* Food processing systems: meat cutting machines, cookie making machines, canning machines, noodle making machines

* Others: speed reducers, electroplating machinery, physics and chemistry machines, paper-making machines, pulp processing machines.

![Small Single Shaft Magnetic Particle Clutches 7]()

Still frustrated about your powder brake, powder clutch, air shaft or safety chucks, tension controllers? And looking for available and enduring ones with warranty?

You’ve come to the right place!

Established in 2003 and located in Dongguan city, SUNRISE GROUP INDUSTRIAL CO., LTD is a professional manufacturer and trader of powder clutches, powder brakes, electromagnetic clutches, electromagnetic brakes, air clutches, air brakes, air shafts, safety chucks, rollers and tension controllers. You name it, we specialize in it!

![Small Single Shaft Magnetic Particle Clutches 8]()

Due to the positive image and quality products, SUNRISE GROUP INDUSTRIAL CO., LTD has gained a large share of the market, along with the products sold in over 30 countries and regions, including US, Mexico, Colombia, German, UK, Australia, Italy, Spain, Portugal, Russia, Korea, Malaysia and eastern European countries etc...

![Small Single Shaft Magnetic Particle Clutches 9]()

![Small Single Shaft Magnetic Particle Clutches 10]()

![Small Single Shaft Magnetic Particle Clutches 11]()

1. When can I get the quotation?

We usually quoted within 24 hours after receiving your inquiry. If you are very urgent to get the price, please call us or tell us in your email, so that we can regard your inquiry priority.

2. How should I place the order?

Please let us know the model number based on our specs for powder clutch, powder brake, air clutch, air brake, electromagnetic clutch, electromagnetic brake and safety chucks. For air shaft and roller, please show us your drawing, or let us know your request, and then we will provide you drawing for confirmation.

3. What’s your MOQ basis?

Normally, we don’t have MOQ request, except the rollers.

4. What about the lead time for production?

Honestly, it depends on the order quantity and the type of our products. For powder clutch, powder brake, tension controller, load cell and edge position controller which is about 3-5 days. For safety chucks, air shaft and roller which need about 15-30days.

5. What is the term of delivery?

We can arrange with EXW, FOB, CIF¡etc. You can choose the most convenient one or cost-effective way.