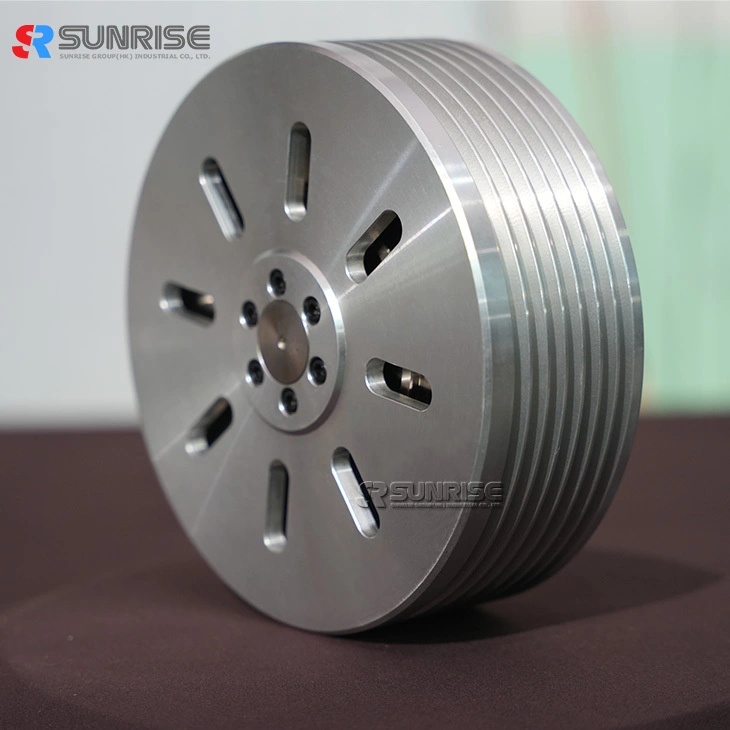

Sunrise outside rotation SGEB Industrial Hysteresis brake for Cable & Wire Machinery

Sunrise outside rotation Industrial hysteresis brakes have been designed to maintain high performance in continuous slip applications through maximum and continuous heat dissipation. The use of high wear resistant particles assures long operational life in high cycle applications.

5.0

Brand:

Sunrise Group

Model:

SGEB-1A

Allowable Rotating Speed:

10000 r/min

Weight:

3.5 kg

Power Consumption (75°C):

250 W

Rated Voltage:

DC24V

Rated Torque:

0.6 Nm

Color:

Silver

Payment:

EXW, FOB,,DAP, CIF...

design customization

Please fill out the form below to request a quote or to request more information about us. Please be sure to upload customized requirement documents or pictures, and we will get back to you as soon as possible with a response. we're ready to start working on your new project, contact us now to get started.

Specification

|

Model No. |

SGEB-1A |

SGEB-3A |

SGEB-10A |

SGEB-30A |

|

Rated Torque (Nm) |

0.6 |

2.5 |

9 |

26 |

|

Power Consumption(75°C) (W) |

250 |

500 |

1000 |

2000 |

|

Max Voltage (V) |

24 |

24 |

24 |

24 |

|

Rated resistance (Ω) |

50 |

28 |

13 |

10 |

|

Max speed (rpm) |

10000 |

6500 |

4500 |

3000 |

|

Weight(kg) |

1.8 |

5 |

16 |

42 |

|

Hysteresis brake dimension (unit: mm) |

|||||

|

Model No. |

SGEB-1A |

SGEB-3A |

SGEB-10A |

SGEB-30A |

|

|

Installation

|

A |

55 |

68 |

92 |

122 |

|

B |

24.5 |

32 |

40 |

53.5 |

|

|

D1 h7 |

50 |

80 |

110 |

180 |

|

|

D2 |

75 |

112 |

168 |

260 |

|

|

D3 |

93 |

140 |

210 |

292 |

|

|

d1 k6 |

11 |

14 |

19 |

24 |

|

|

d2 |

M4 |

M5 |

M6 |

M8 |

|

|

d3 |

M5 |

M6 |

M8 |

M12 |

|

|

d4 |

60 |

100 |

130 |

215 |

|

|

a |

3 |

4 |

4 |

6 |

|

|

b |

2 |

2.5 |

3.5 |

4 |

|

|

c |

7 |

8 |

12 |

16 |

|

|

L1 |

23 |

30 |

40 |

50 |

|

|

L2 |

18 |

25 |

28 |

36 |

|

|

V P9 |

4 |

5 |

6 |

8 |

|

|

W+0.2 |

2.5 |

3 |

3.5 |

4 |

|

Hysteresis clutch|brake application

Textile machinery

Fiber twisters, treatment machines, weaving machines

Metal fishing systems

Extruders, wire stretchers, presses, welders, steel wire retractors, cutters, pipe makers, wire winding machines

Machine tool systems

Lathes, Millers, steel extruders, CNC lathes, specialized machinery

Transportation equipment

Hoists, feeders, conveyors, rollers, winders

Paper- making systems

Bag-making machines, box-making machines, slitters, book-making machinery, cutters, copy paper machines

Other machinery

Printing mchinery, wood-working machinerylaminators,testing machinery,food processing machinery, Li-battery machinerytire machinery

Application scenarios

Cautions on Safety for hysteresis clutch and hysteresis brake

01

Erroneous handling may cause a dangerous situation in which the possibility of death or serious injury is expected.

02

Never use the unit in an atmosphere in which inflammation or explosion is expected.

03

Sunrise Group is not responsible for any damage or trouble caused by repair, disassembly or modification of the product by any third party other than Sunrise Group.

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Feel Free To Contact With Us

If you have any questions about our products or services, feel free to reach out to customer service team.

Related Products

no data

CONTACT US

ADDRESS

Sunrise Group (Dongguan) Industrial Co., Ltd

Add: 5th floor, cannes international building, gangkou road, nancheng district, dongguan city, guangdong province, china. 523000

Sunrise Group (Hk) Industrial Co., Ltd

Add: RM03, 24/F, Ho King Comm CTR, 2-16 Fayuen ST, Mongkok Kowloon, Hong Hong