High-Performance Durable YHSA Hysteresis Clutch for Wire Machinery

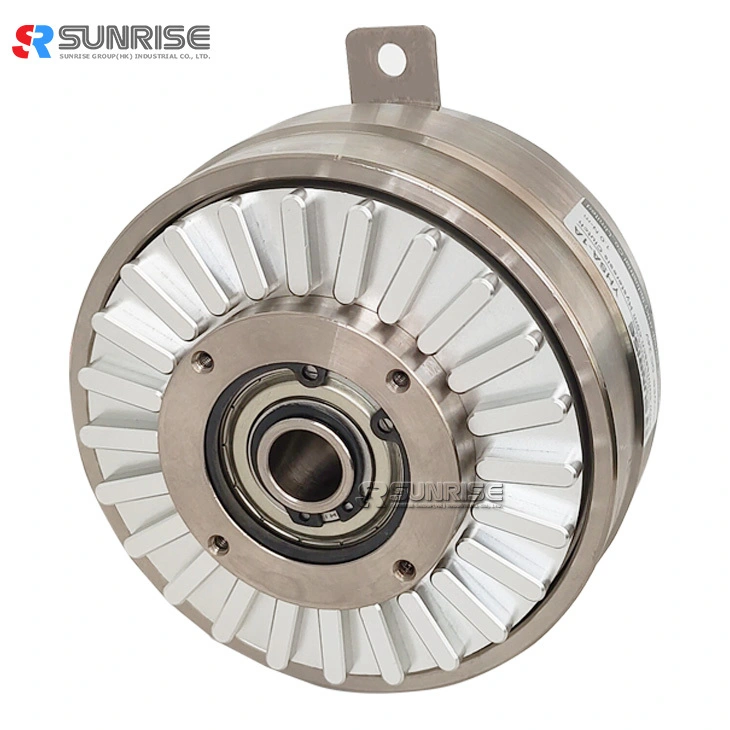

Fig. 1 Structural diagrams of YHSA-1A hysteresis clutch (representative examples)

Hysteresis Clutch Structure And Principle Of Operation

● Figures 1 show typical structures of hysteresis clutch.

● The hysteresis clutch is composed of three parts: stator, first rotor and second rotor.

● The stator has an exciting coil contained inside, and the first rotor comprises inner and outer magnetic poles. Between these magnetic poles, a cupshaped permanent magnet (not magnetized) of the second rotor is interposed.

● Suppose the first rotor is rotated to excite the exciting coil, a rotating magnetic field is generated in a gap formed by the inner and outer magnetic poles of the first rotor, and the permanent magnet of the second rotor placed in the gap is magnetized, but since the permanent magnet has a hysteresis characteristic, the change of polarity of the permanent magnet is later than that of the magnetic poles, thereby coupling the first rotor and second rotor magnetically, so that torque can be transmitted.

Hysteresis Clutch Feature

Specification

|

Model No. |

YHSA-1A |

YHSA-2A |

YHSA-4A |

YHSA-6A |

|

Rated Torque(Nm) |

1 |

2 |

4 |

6 |

|

Power Consumption(75°C) (W) |

90 |

120 |

180 |

230 |

|

Max Voltage (V) |

24 |

24 |

24 |

24 |

|

Rated resistance (Ω) |

27 |

22 |

17 |

13 |

|

Max speed (rpm) |

3000 |

3000 |

3000 |

3000 |

|

Weight (kg) |

4 |

6.5 |

11.5 |

16.5 |

|

Hysteresis clutch dimension(unit: mm) |

|||||

|

Model No. |

YHSA-1A |

YHSA-2A |

YHSA-4A1 |

YHSA-6A |

|

|

Installation |

L1 |

68 |

79 |

93 |

112 |

|

L2 |

64 |

75 |

87 |

110 |

|

|

L3 |

37 |

50 |

55 |

75 |

|

|

L4 |

5 |

5 |

6 |

6 |

|

|

L5 |

20 |

20 |

25 |

25 |

|

|

L6 |

72 |

82 |

100 |

110 |

|

|

L7 |

65 |

75 |

90 |

100 |

|

|

D1 |

118 |

146 |

172 |

196 |

|

|

D2(h7) |

62 |

72 |

92 |

110 |

|

|

D3 |

55 |

62 |

82 |

100 |

|

|

D4 |

20 |

25 |

30 |

50 |

|

|

D5 |

15 |

19 |

24 |

38 |

|

|

D6 |

47 |

62 |

75 |

80 |

|

|

D7 |

25 |

35 |

45 |

50 |

|

|

R |

7 |

7 |

9 |

9 |

|

|

M |

4-M4 |

4-M5 |

4-M6 |

6-M6 |

|

|

d(H7) |

11 |

14 |

19 |

30 |

|

|

W(F7) |

4 |

5 |

5 |

7 |

|

|

T(+0.2 |

12.5 |

16 |

21 |

33 |

|

Hysteresis Clutches Exciting Current VS Torque

Hysteresis Clutch Torque Adjustment

● The relation of torque and exciting current is almost proportional as shownabove, and therefore by adjusting the current, the torque can be easily adjusted.

● Set to a proper value in consideration of the finish of the product or working condition.

Hysteresis Clutch|Brake Application

Application scenarios

Hysteresis Clutch Maintenance

Turn off the power, and make sure rotating elements are stopped.

● Unlike the other type of clutch and brake, hysteresis clutch and hysteresis brake are noncontact type. Therefore, it requires no adjustment which is otherwise required to compensate time-change. but please avoid to use the unit in the high temperature or high humidity or in the atmosphere full of dust.

● Check the coupling mounting bolts and others for looseness.

CAUTION For Hysteresis Clutch